Process Tutorial

Guide for index tab layouts

20/10/08 18:28 Filed in:

Index tab cutting

Index tab dividers are a great way to organize material for

projects. They are the most popular and efficient way to arrange,

sort, and categorize information in Three Ring Binders, Plasticoil,

Pasticomb, and Double Loop Wire books. Before getting started on a

tab project there are a few questions to be considered:

What is the depth of the tab? The

depth is the length of the tab extension from the edge of the sheet.

Standard sizes are ½”, 3/8”, and ¼”

What is the size of the inset?

The inset is the distance from the edge of the sheet to the first

tab.

What is the width of the tab? The

width of the tab is figured by taking the inset, (usually ¼” or ½”)

subtracting it from the sheet size, then dividing by the number of

tabs. For example: If your sheet size is 11” and your inset size is

1/4” each side (1/2” total) with 6 tabs, then you subtract ½” from

11 leaving 10 ½” divided by 6 equals 1 ¾” for each tab. This will

help you properly layout your copy.

What is the bank? The

bank of the tabs is the number of tabs on a single row of the face

edge. To figure the size: see above.

Will they be Mylar Reinforced on tabs?

Mylar reinforcing is the process of applying a clear or colored

plastic film to the tabs for strength and durability. There are a

number of colors to choose from so consider these options to add

some flare to your project.

Please note: Mylar cannot be applied after tabs are cut.

Will the tabs be Mylar Reinforced on binding edge?

Edge reinforcing is a clear strip of mylar applied to the binding

edge to help prevent tearing.

Will there be any other finishing required for this project?

A number of things may be done after tabcutting including:

collating, shrinkwrapping, drilling, and inserting into pocket

folders or binders. Just let us know what your needs may be.

One final note:

When a set of tabs will be Mylar Reinforced be wary of printing copy

on the body of the tabs, as the extreme heat used for this process

has been known to cause smudging and streaking of the inks. Even

with heat resistant inks a test run may prevent any unforeseen

problems. If this occurs we may have to Mylar reinforce by hand,

increasing the cost.

Please feel free to download our

GUIDE FOR TAB LAYOUTS

Foil Stamping

16/08/08 09:49 Filed in:

Foil & Embossing Processes

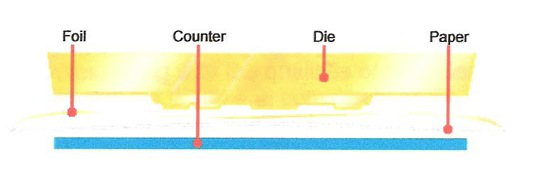

Foil stamping is actually a simple process and consists of mounting

a die to a heated platen in a press. Foil is then passed between the

die and the substrate to be foil stamped. The press then applies a

predetermined amount of pressure to the die,

foil and substrate causing the color layer of the foil to transfer

to the substrate. Most all foil stamping foils consist of 5 layers :

Film carrier

Release coat

Color coat

Metal coat

Adhesive coat

There are a wide range of foil colors and release’s for different

applications so consult with us for color charts, stock

recommendations and image characteristics to produce an award

winning project !!!

Foil Embossing

16/08/08 04:44 Filed in:

Foil & Embossing Processes

Foil embossing uses the same process as foil stamping but the dies

are significantly different and there is a male counterpart to the

die. Foil emboss dies start out as engraved embossing dies, the

outside is relieved creating a cutting edge around the image. When

the die is heated and pressure is applied the foil and the substrate

are pushed into the die with the male counterpart leaving all the

detail and the image completely covered with foil. The same process

can be achieved using a deboss die that pushes the image down as

opposed to raising the image as with embossing. Remember to consult

us on any foil projects. There are a lot of variables with stocks,

inks and coatings to consider. The number one rule to remember when

stamping on inks or coatings is always print with Wax Free

materials!!

Embossing/Debossing

19/07/08 09:19 Filed in:

Foil & Embossing Processes

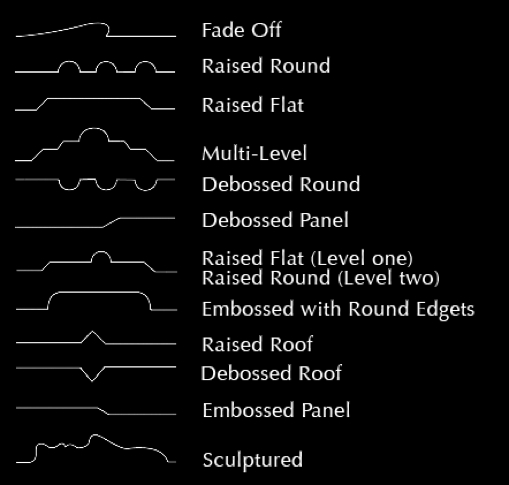

The art of using either a machined or photo chemically engraved die

to raise or lower an image in a substrate (paper , leather, plastic

etc. ). Embossing or debossing a preexisting image is considered

register where as no exsisting image is considered blind. Embossing

or debossing dies can be made from magnesium, copper, or brass.

Magnesium and copper are photo chemically engraved where as brass is

machined or hand tooled. Embossing or debossing can be simple as a

single level or multiple levels in a variety of profiles. The most

elegant are sculpted brass dies which are generally hand tooled. The

die engraver should be called an artist due to the artistic value

that is required to transfer an image into brass that has all the

detail of a sculptured statue. Embossing/debossing is best when a

heavy textured cover stock is used (80# and up) to enhance the

intricacy and depth of the image and will take more heat and

pressure to give the image a burnished and ironed out effect.

Embossing/ debossing is achieved when the female die is mounted and

heated up in a press, the female counterpart is then transferred to

the platen of the press. The paper is fed between the die and

counter, pressure is applied pushing the paper into the die

transferring all the detail and smoothing out the paper.

Die Cutting

18/07/08 12:52 Filed in: Die Cutting

This process uses a steel rule cutting die. Dies are either Jig or

Laser dies the latter being the most accurate but simple 1 up dies

are generally jig dies and multiple up simple or intricate dies

being laser. Dies consist of .625 birch plywood and a variety of

cutting rules, scoring rules, perfing rules, punches and ejection

rubber that are inserted into the die board after it is machined.

The die is mounted in the press and make ready begins by adjusting

pressure on the press to cause the cutting rules, perfing rules and

punches to cut and scoring rules to crease the paper for folding.

There is a pre manufactured creasing matrix that creates the female

channel that is added to the bottom cutting plate opposite the die,

this channel lets the scoring rule push the paper into it to form

the bead for proper folding. Kiss cutting is used for peel off

labels and for cut scoring. The only difference is the cutting rules

are made ready to only cut through the top layer of stock. The above

processes can be done cold or with heat. Die cutting cold is the

most common and heat being used for plastics, vinyls and troublesome

paper projects where scoring cracks due to coating issues. Please

contact us for all your die cutting needs. We make 95% of all steel

rule dies in house and have several Laser die manufacturers as

vendor partners to round out our team.

Film Laminating

18/07/08 11:53 Filed in:

Film Laminating

This process consists of applying a cold or thermally activated film

to a substrate for cosmetic appearance or protection. There are a

wide variety of film laminates but the most common are OPP

(polypropylene), PET (polyester), AGS ( glueable, stampable) Lay

flat (nylon),Hi Tac digital print films, they come in clear, matte

and satin finishes. There are also a lot of specialty films

available textured, holographic, window cling , floor graphic non

skid to name a few. Please call for any other specialty film

laminates you might need. Films come in thickness ranging from 1.3

mil – 10 mil the most common being 1.3 - 3.0 mil.

The thicker laminates are more for protection and stiffness than

cosmetic value. Most film laminates are applied using heat ,pressure

and are run through a series of heated rollers transferring the film

to the substrate being fed through the machine. There are a lot of

variables to consider when film laminating to insure proper

adhesion, printed sheets need to be wax, silicon free and have at

least a .250 coating free border on all four sides. Please feel free

to call with questions regarding any laminating projects you may

have and get ready to have finished piece with a lot of “Pop” !!!!

Ordering Dies

16/07/08 09:57 Filed in:

Ordering Dies & Artwork - Proofing

There are 3 primary materials we use when making dies in to order

achieve the desired results in all stamping and embossing processes.

They are magnesium, copper, and brass. Many factors are used to

determine which of these materials to use, including: Complexity and

detail of the design, run length, and the necessary lifespan of the

die. We consult with our clients on each job, as each job is

different, to pick the material best suited for achieving your

desired goals.

Magnesium Dies:

These dies are most commonly photo-etched. They are the most cost

effective method for flat stamping and some single level embossing

applications. These dies are best suited for short runs, but are

limited based on image area and type of stock. They work best with

small to medium sized surface areas, but should not be used when

fine detail or uneven distribution is needed. Paper stocks that are

smooth or coated work best when using magnesium dies.

Copper Dies:

These dies are also produced by a photo-etching process, and they

are also used for flat stamping and single level embossing. However

copper is a harder metal and better heat conductor than magnesium.

Therefore it has better etching attributes and has a longer lifespan

for extended or repeated runs. Copper’s durability is also an

important factor when stamping medium to large solid areas, where

more tonnage and pressure are needed. This helps ensure the die will

not crush under the pressure. Copper’s conductive properties allow

it to maintain heat very well. This is most important on high speed

equipment, where the equipment’s speed and action can cool the die

temperature. Finally, if you are using textured and recycled stocks

a copper die is the way to go.

Brass Dies:

Brass is the most versatile and durable of these 3 metals. These

dies are hand crafted or milled on a CNC, and are used when the

utmost quality is required. Brass is the only metal suitable for

multi-level and sculptured embossing. It is also used when a bevel

is required and for most combination processes, including

foil/embossing and foil/debossing. Because they can now be machine

milled, brass dies are extremely precise.

Preparing Artwork

15/07/08 11:06 Filed in:

Ordering Dies & Artwork - Proofing

Steel Rules Dies

We have our own inhouse dieshop, and do most of our diecut dies on

the premises. Dies that require more detail are sent out to a laser

diemaker. In both instances the file requirements are the same. Die

files should be saved as a PC formatted EPS file. There should be no

errant or unnecessary lines. We also require a drawout or sample of

some type with all scores, perfs, and knives clearly marked.

We also utilize Cimex, a CADD program designed specifically for the

Steel Rule Die industry, to further assist you in achieving the best

possible product. Cimex allows us to cut prepress samples that are

extremely accurate. After any changes have been made and we get an

approval, we use the exact same file to generate the image drawn on

the dieboard. This allows us to draw dies that are much more

accurate than anything drawn by hand. Images for samples should also

be saved as a PC formatted EPS file.

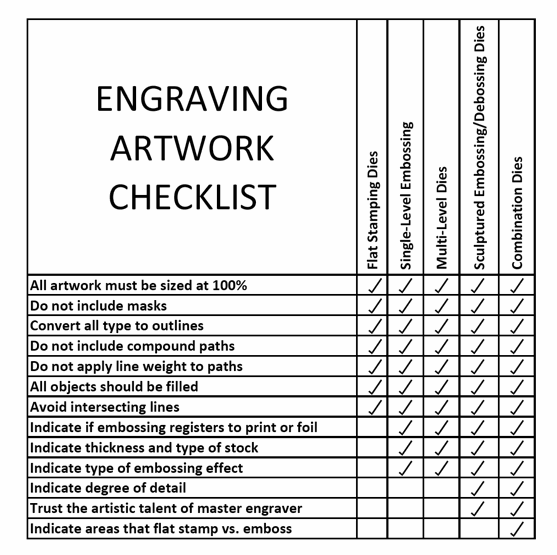

Foilstamp and Emboss Dies

Digital files have now become the preferred method for receiving

information to make stamping and single level embossing dies.

Diemakers suggest that files be saved as an original art file

instead of a file in a layout program such as QuarkXPress,

Pagemaker, or InDesign. Most die makers prefer files in PDF format.

The files should be clean and crisp, as any flaws will show on the

die. All images should be 100% of size and solid line art without

the use of screens. The artwork should be saved at 600 dpi or higher

to ensure a crisp image. Some guidelines to go by are:

Do not include masks

Convert all type to outlines

Do not include compound paths

All objects should be filled

Avoid intersecting lines or images

When preparing artwork for brass multi-level and sculptured dies,

any embossing effects must be indicated. The most common effects are

either raised round (round lift), raised flat (beveled flat lift),

or raised roof (raised faceted).

Sculptured embossing dies are hand engraved by master engravers.

Although the designer has a say in how much detail will be necessary

and where it will be placed, they will also have to rely on the

master engraver’s expertise. If only part of an image is to be

sculpture embossed it is best to separate the layer that is to be

embossed from the layer not embossing so as to avoid confusion.

Combination foil/embossed and foil/debossed dies follow the same

guidelines as above for artwork. However, if parts of the image will

be foil/embossed while other parts will only flat stamp, this must

be clearly marked on the artwork.

Proofing

15/07/08 11:00 Filed in:

Ordering Dies & Artwork - Proofing

Proofing is a very simple and helpful tool in stamping. The most

difficult thing is time constraints. If given enough time we can

make a proof or sample with just 3 basic tools: a sample roll of the

foil, the die(s), and a few sample sheets of the stock. This is

always a good idea when time permits to prevent unforeseen problems.

Glossary Of Trade Terms

14/07/08 22:55 Filed in:

Glossary of Trade Terms

Artwork, Camera-Ready

Final drawings or stats in high contrast black and white, used to

reproduce the image with all blemishes and imperfections removed.

Beveled Edge

The edge of an embossed or debossed area made to a specific angle to

the proper plane. These beveled edges range from 30 to 80 degrees

from the paper and image planes.

Blind Emboss/Deboss

Raising or lowering the image without registering to print or foil.

Border

Referred to as a line to be printed, stamped, embossed, or debossed.

It is open inside it’s perimeter, rather than solid.

Chiseled

A shape put into embossed or debossed images resembling a V-shape.

Color Register

Having design elements fit each other through various press

operations, such as printing, embossing, foil stamping, folding, or

diecutting.

Deboss

Lowering the image below the paper level.

Die, Combination

A female die used to emboss and hot stamp simultaneously. It has a

cutting edge to aid in a clean cut of the foil around the image

area.

Die, Counter

A male counterpart molded from the original female dies used to

press the paper into the die to emboss or deboss.

Diecutting

Cutting the paper or substrate with a knife-edge steel blade. These

can be straight single cuts, slots for insertion of other items,

holes cut to any shape and size, and custom images provided by the

client.

Die, Duplicate

In embossing dies, molded duplicates made from the original dies.

These can be made of various materials. These are used to cut cost

when making multiple dies.

Die, Embossing

The female die hand sculpted, machine-tooled, or photo-etched. Used

to emboss or reshape the paper under heat and pressure.

Die, Foil-Embossing

Same as Combination Die

Die, Stamping

A photo-etched or machined die used to flat stamp foil to paper or

other substrate.

Die, Steel Rule

A cutting die used on letterpress to pierce or cut out paper.

Generally made type high (.918”) with 1/32” thick steel rule blades,

or rules, cut and bent to specific patterns and mounted in a wooden

base.

Domed

A shape put into embossed or debossed images resembling a

semi-circle or half-moon.

Emboss

Raising the image above the paper level.

Foil

General term for hot stamping material, consisting of a film carrier

coated with a release agent, a color coat or metalized aluminum, and

an adhesive coat.

Foil Embossing

Raising the image and applying foil at the same time with one press

run, as with a combination, foil embossing die.

Foils, Dusted

Foils that utilize a bronze powder on the carrier. Easily applied,

but easily rubbed off without an over-coating.

Foils, Flat Pigment

Opaque foils of intense color, resembling flat paint.

Foils, Gloss

Transparent foils glossy in appearance.

Foils, Gloss Pigment

Opaque foils of intense color, resembling glossy enamel paint.

Foils, Holographic

Foil that has holographic images embossed into it, allowing the

viewer to view the stamped holographic image three-dimensionally

without special eyewear.

Foils, Metallic

Metallized aluminum foils available in many colors, either shiny, or

satin in finish. The most widely used are gold and silver.

Foils, Patterned

Foils manufactured with specific patterns rather than one color.

These range from woodgrains, marble, or multi-colors to the new

three-dimensional holographic patterns or images.

Foils, Pearlescent

Similar to gloss foils, having a translucent pearl color.

Foils, Tint or Pastel

Flat or dull translucent stamping foil. Can be applied in varying

degrees of color density by changing the press temperature when

stamping.

Glazing

Smoothing a textured stock with controlled heat and pressure. Gives

a shiny effect.

Gripper Edge

The edge of the sheet which is pushed or pulled against a

predetermined stop on the press. For registering purposes, the same

designated edge is used during all processes.

Hologram

A three-dimensional picture that is made on a photo-sensitive glass

plate using a laser as the light source. From this plate a shim is

made and the image is stamped into a metallic foil.

Hot Stamping

Applying foil with the use of heat, pressure, and dwell to various

substrates, such as paper, plastic, wood, and leather.

Image Area

Any element of design to be printed stamped or embossed.

Light or Color Fastness

The ability of foil products to resist fading when exposed to light.

Multi-Level

Raising and/or lowering an image two or more levels.

Non-Image Area

Background area, as opposed to image area. The carrier, paper, or

substrate on which the image is printed or stamped.

Paper, Uncoated

Paper that is better for embossing because it’s soft finish has less

tendency to wrinkle or crack. Foils will appear less glossy on these

stocks. Uncoated textured sheets may sometimes be very difficult to

smooth out when foil stamped.

Paper Level

Reference point for all embossing or debossing.

Photo-Mechanical

Sometimes referred to as chemical milling. Image is exposed with a

light-sensitive emulsion on film positive or negative, then

acid-etched to a specific depth and angle. Depending upon the die

function, the image is etched into an embossing die and the

non-image area is etched into away on a stamping die.

Plasticizer Migration

When foil is stamped on PVC or other plastic products, the

plasticizer migrates from the foil area to the surface of the

plastic piece. The result is that the metallic foil will fade.

Press Proof

A short press run for approval by the client prior to the actual

production run. It uses the specified paper, inks, dies, etc. for

the press operator to match in actual run.

Reverses

Openings in the image where the background or paper show through the

printed or foil areas. Can either be type or design elements.

Scorching/Heat Tint

Changing the paper color in the embossed or debossed area by using

excessive heat, which creates a two-toned effect, with the image

being the darker tone.

Scoring

Sharply creasing a material to facilitate folding. It should be made

the same direction as grain of paper when is of folding is the

primary concern. For greater strength, a score can be made

perpendicular to the paper grain.

Sculpted Embossing

Raising and/or lowering an image with sculptural realism with a

variety of shapes, angles, and edges, as opposed to flat levels.

Examples: A sculpted image of a face, a bird’s feathers, or the

muscle definition of an athlete.

Single Level

Raising or lowering an image one flat level from paper level.

Step and Repeat

Same image precisely repeated one or more times horizontally and/or

vertically to predetermined distances. These distances from one

image to another are referred to as “center” when measured from a

point on one image to the same point on an adjacent image.